LoveChip Enhances Electronic Market Standards with Top-Tier Quality Assurance Processes

LoveChip Semiconductor champions elite QC standards and robust quality assurance in electronic component distribution.

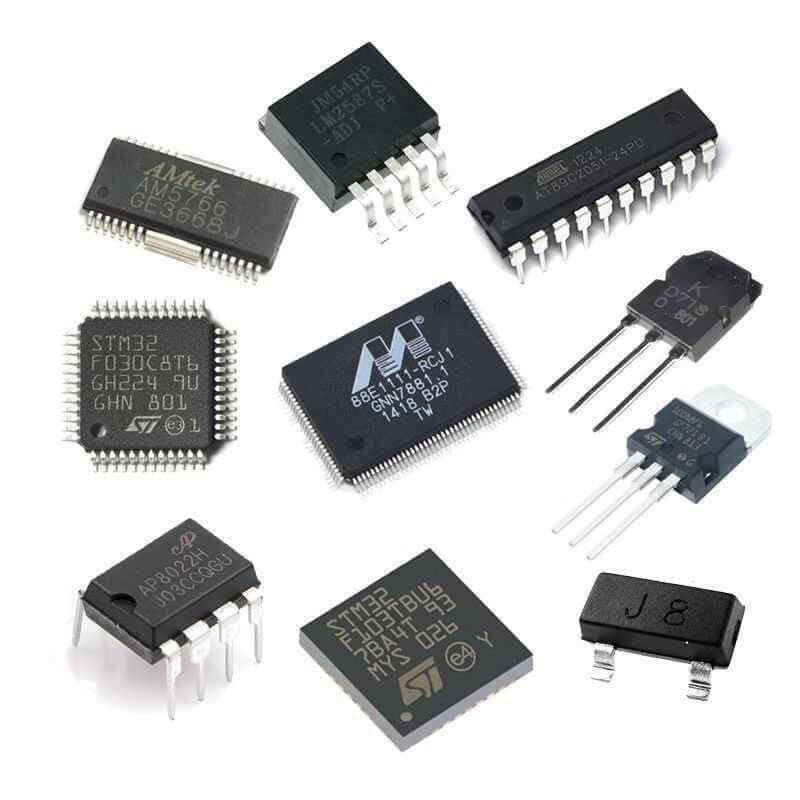

LoveChip Semiconductor is a leading electronic components distributor, renowned for its comprehensive one-stop procurement platform. This platform simplifies the sourcing of high-quality electronic components, integrating sourcing, logistics, and payment processes to provide a seamless and efficient experience for clients. In the pursuit of product quality, LoveChip has always insisted on using top-notch equipment and strict quality control processes to ensure that every product meets high-standard quality requirements.

Comprehensive Quality Control Processes

LoveChip’s quality control process includes five key stages: receiving, quality inspection, storage, documentation, and dispatch. Each stage has specific operational standards and quality inspection criteria:

1. Receiving and Counting: Upon arrival, each batch of goods is thoroughly counted to ensure the accuracy of quantities.

2. Quality Inspection: Each product’s appearance and packaging are meticulously observed using microscopes and magnifying glasses to ensure there are no surface or packaging defects.

3. Storage and Documentation: For products that need to be dispatched on the same day, appearance documentation or internal structure X-ray documentation is conducted, followed by vacuum packaging and labeling. All operations are completed with a strict verification to ensure that each product meets all regulations and standards before dispatch.

4. Moisture-Controlled Storage: For products that do not need to be dispatched on the same day, they are stored in a moisture-controlled warehouse to ensure that the quality of the products is not affected while awaiting dispatch.

State-of-the-Art Equipment for Uncompromising Quality Checks

Equipped with cutting-edge technology such as the SEAMARK X5600 X-RAY and sophisticated baking machines, LoveChip Semiconductor ensures that every component and internal structure meets rigorous quality standards before dispatch. This equipment plays a crucial role in revealing minute internal details and addressing potential quality issues proactively.

Third-Party Quality Verification

To further bolster customer trust in product quality, LoveChip Semiconductor supports and encourages the acquisition of third-party quality inspection reports from esteemed organizations like White Horse Testing, providing an additional layer of quality assurance.

Exemplary Quality Certifications and Management Systems

LoveChip Semiconductor’s commitment to quality management is recognized through multiple international standards, including ISO 14001, ISO 9001, and Dun & Bradstreet certifications. These certifications not only reflect the company’s adherence to stringent environmental and quality controls but also bolster its credibility in global operations.

Reliable Product Sourcing through Quality Supply Chain Partnerships

Beyond strict QC processes, LoveChip Semiconductor emphasizes collaboration with esteemed brands and suppliers to ensure the reliability of product sources. By forging strong partnerships, the company is able to swiftly adapt to market and customer needs, offering a more diverse and superior range of products.

Conclusion

With these robust quality controls and a commitment to continuous improvement, LoveChip Semiconductor is dedicated to providing the highest quality products and services. The company believes that by continually enhancing its products and services, it can excel in a competitive market, becoming the preferred partner for an increasing number of customers.